Forsyningskjeden for bad og kjøkken i USA er forstyrret

According to US media reports, the disruption to the supply chain continues to have a serious impact on material prices, produktetterslep, fraktkostnader og prosjektsykluser for kjøkken og bad. Mens dagens situasjon kan være midlertidig, it is estimated that it will continue into next year.

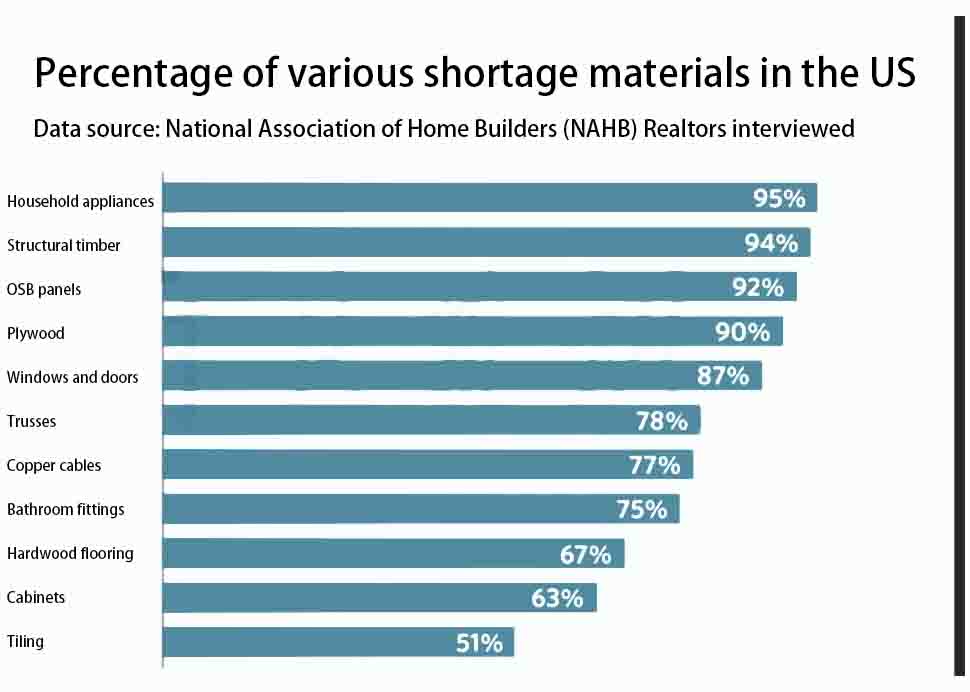

Ifølge den siste undersøkelsen fra Boligprodusentenes Landsforbund (NAHB), the situation has deteriorated significantly “dramatisk” since the same period last year. The impact has been wider, with shortages of bathroom fittings, husholdningsapparater, fliser, cabinets and other key components used in the manufacture of refrigerators, ovner, oppvaskmaskiner, mikrobølger, washing machines and dryers. The shortage of bathroom fittings reached 75 percent of the real estate agents surveyed, while the shortage of tiles reached 51 prosent. The most serious shortage was for household appliances, på 95%.

Material shortages are now more widespread and deeper than at any time since 1990, and the slight increase in costs has exacerbated this effect, reducing builders’ confidence in the market to its lowest level in a year.

Leverandører av bad, hjem dekoratører, distributører, real estate agents and others are facing a year-long ‘storm’ av økende etterspørsel, kombinert med materialmangel, logistiske utfordringer og pandemier. While remodeling demand is soaring as vaccination rates increase and the DIY home market is fuelled by emerging lifestyles, Forstyrrelser i forsyningskjeden har ført til alvorlig mangel på viktige byggeprodukter. Samtidig, supply constraints are causing material costs to soar.

I følge den siste markedsindeksen for kjøkken og bad (heretter: KBMI, the US Kitchen and Bath Market Index) utarbeidet av National Kitchen and Bath Products Association (NKBA), John Burns Eiendomsrådgivning, supply chain issues coupled with rising material prices and transportation costs are forcing an increasing number of home design companies to face longer lead times, while needing to seek alternative sources of supply and increase prices to protect margins.

Ifølge KBMI, U.S.A. Kjøkken og bad markedsindeks for første kvartal av 2021, 45% of dealers and designers surveyed said material shortages and product pricing are impacting project lead times. 60% of manufacturing facilities surveyed noted average lead times of six weeks or more, en betydelig økning fra forrige kvartal. Capacity is being severely constrained by longer delivery times for raw materials and significant freight delays. i mellomtiden, 67% of real estate vendors surveyed noted that work had been backlogged for more than three months, og 21% noted that the backlog would continue until the end of 2021.

i mellomtiden, US-based factories are beginning to add capacity and restructure their supply chains. In June this year, it was reported that DEVIDA Bathrooms announced that it would “prioritere” certain brands of products while suspending production of other ranges. The company said that this situation was expected to continue until the fourth quarter of 2021, and noted that while no new orders would be taken during this period, existing orders would not be affected by the decision.

In addition to the US, Tyskland står også overfor en krise med forstyrrelser i forsyningskjeden. The German Bavarian plumbing and bathroom industry is already experiencing shortages of steel and brass, starting with wood and plastic. På bare ett år, the price of insulation boards has risen by 10%. Steel has risen by 30 percent and roofing sheets by 31 prosent. And the global price of copper has risen by 80 percent in the last 12 måneder.

In addition to delivery problems, mangel på fagarbeidere rammer også byggebransjen. Rekruttere fagarbeidere, inkludert i Kina, har blitt den største vanskeligheten med å rekruttere arbeidstakere.

Besøk flere nyheter på Viga.cc Nyheter

iVIGA Tap Factory Supplier

iVIGA Tap Factory Supplier